Competition among manufacturers and operators of offset printing machines is fierce. Along with quality and the productivity of systems, customized configuration is gaining in importance rapidly. That is why the print machine manufacturer manroland sheetfed is offering individual, customer-tailored retrofitting for machines to increase their flexibility. A sheet numbering system is now being developed together with REA JET for one international packaging producer with the goal of automated quality control.

The technology, called inline numbering, was developed as an optional feature for a Roland 700 HiPrint and can be integrated with all models in the 700 series. manroland offers customers an individualized customization of machines from a single source and with REA JET is bringing an experienced partner on board that has established itself with over 30 years in the market as a specialist in industrial marking. “Working together with REA, we have discovered a solution that enables seamless tracking of production for the customer and further increases the value of the print machine investment”, explains Dr. Holger Wiese, Head of Research at manroland in describing the collaboration.

Consecutive number marking

The sheet numbering in conjunction with the ROLAND InlineInspector 2.0 is an attractive alternative to the traditional solution, in which sheets were marked in stacks with a tab inserting machine. But with inline numbering, each individual sheet is marked for quality with a permanent serial number, which can be used for tracking at any time. In case of discrepancies from the print specifications, the relevant sheet can be easily identified, separated, and removed.

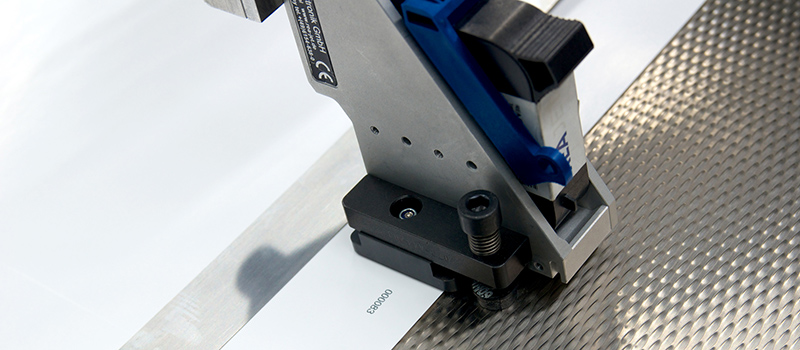

For this method, the thermal inkjet printer REA JET HR was integrated with the Roland 700. The sheets are then singled out directly on the system table and an ongoing number is printed in the margin. The signaling for the high-resolution, contact-free marking is made by laser sensor. The sheet feed through the digital input results in the print trigger for each individual sheet.

Costs are lower –productivity is higher

The InlineInspector 2.0 registers and logs possible problems, thereby establishing a consistent control process and making the printing transaction transparent. Individual sheets with errors can be quickly localized using the serial number generated by the REA JET HR and consistently removed. This reduces waste and lowers costs while increasing quality. There is also an increase in productivity because of the automation: 18,000 sheets can be processed per hour.

The inspiration for the combination of sheet numbering and quality control originated with a customer request. But space on the system table is limited and therefore the print heads must be compact and flexible for positioning. After a test phase, the REA JET HR Inkjet printer was ultimately implemented together with the inspection system.

Maintenance-free system

The compact REA JET HR was impressive right down the line and with its narrow design and many interfaces was integrated smoothly. In addition, there are no inconvenient tubes and the pint head can be pushed back as needed. Thanks to the HP technology, the system is maintenance-free, has no solvent-based inks or thinner and is therefore also suitable for critical industries like pharmaceuticals and the food industry. The short setup time has also been well received at manroland, as well as the quick cartridge change, the good price-performance ratio, and the low ink consumption: With one ink-cartridge, 1.5 million sheets can be numbered with a resolution of 150 dpi.

Another advantage was the proximity to REA Elektronik, as the company like manroland is based in Hessen, Germany. Once there was a deadline to be met, there was a certain time pressure to complete the installation. “REA JET turned out to be very flexible. We benefited from the short distances and REA was also impressive from a technical standpoint”, said Dr. Wiese of the successful collaboration. In the future, REA JET will therefore be the first choice for additional expansions and for original equipment as a listed marking solution.

The companies:

manroland sheetfed GmbH, based in Offenbach am Main, is a leading international manufacturer of offset print machines for job, packaging and publications printing. The company was founded in Germany in 1871, is one of the longest standing traditional print machine producers and today has offices in more than 40 countries worldwide. manroland sheetfed GmbH is a wholly owned subsidiary of the privately held British company Langley Holdings plc., a global engineering concern.

REA JET develops and produces marking and coding systems for industrial marking. Its portfolio includes inkjet printers, laser and spray mark systems, labeling solutions, as well as ink and consumable products. REA JET and the manufacturer of code verification systems, REA VERIFIER, are divisions of REA Elektronik GmbH based in Mühltal, near Frankfurt am Main. REA Elektronik was founded in 1982, is owner-operated and employees a staff of over 300 (2014). All products are 100% made in Germany.