Definition of Task

- Cosmetic pens have fit tolerances due to production

- In order to compensate for such tolerances during assembly processes, a small drop of oil is sometimes found to be helpful

- The oil also prevents any squeaking during screwing or unscrewing, and makes the pulling-off and secure attachment of the cap easier

Special Product Specification

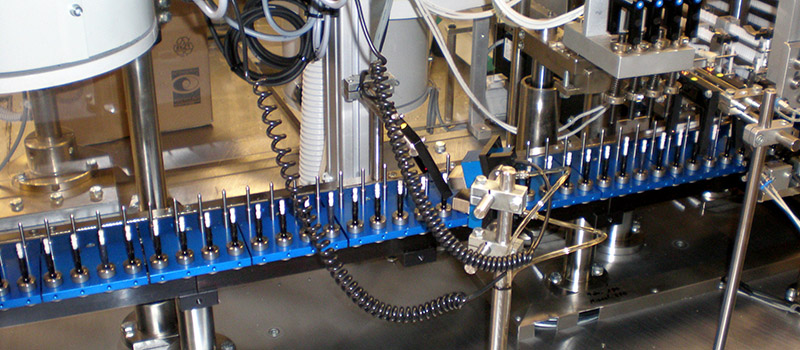

- Oiling takes place at high clock frequency while the product is passing the print head

- The oil must, however, be applied precisely and exactly targeted to the component surface

- EDS system can be adjusted to process oils in different viscosities

REA JET Solution

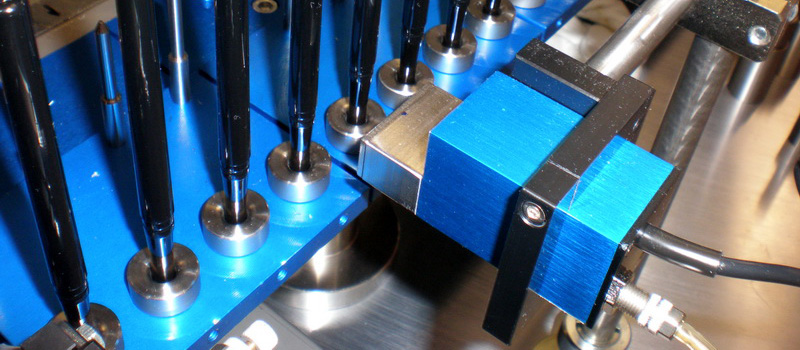

- REA JET EDS One Dot Marking System

- Medium: Skin gentle oil

Advantages of the REA JET Solution

- Easy assembly of the touching plastic parts by applying oil

- Oil stops squeaking during screwing or unscrewing

- Easy fine-adjusting of the amount of oil with the REA JET EDS controller

- High process reliability due to exact reproducibility of the applied amount of oil

- No oil contamination at the production line

- Satisfied customers due to easy fitting and removal of the cap with a “click“ sound