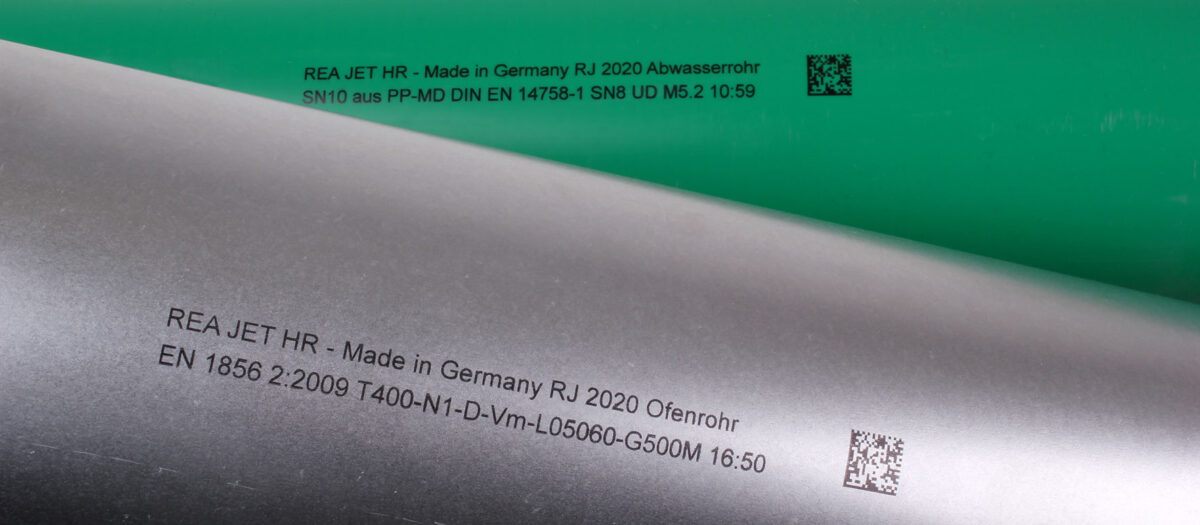

At the booth, the REA marking experts will present robust inkjet, laser and spray technology systems for marking metal, plastic and concrete pipes. Reliable and well proven, even under difficult environmental conditions. All marking technologies (inkjet and laser) from REA JET can be controlled via the single operating concept called the REA JET TITAN Platform. This saves time, money and considerably reduces the risk of misuse.

NEW – in addition to inkjet and laser systems, the REA JET TITAN Platform can now also be used to control the marking of large codes, texts and logos with spray mark blocks from the Spray Mark Technology product family. This technology is particularly in demand when markings have to be applied at great print heights that are perfectly legible even from a greater distance or at surface temperatures of more than 300 degrees Celsius.

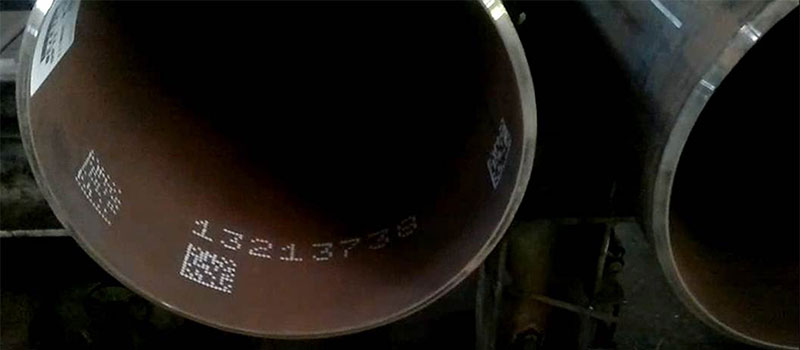

REA JET will also present the latest generation of DOD 2.0 Large Character Inkjet Printers. Proven technology, further improved. This system is ideal for marking alphanumeric characters, logos and 2D matrix codes. The use of pigmented inks creates a very legible, durable marking on all smooth and absorbent surfaces, even if they are coated with oil or scaled.

REA JET has the latest laser systems using CO2 and fiber laser technology in its product range for counterfeit-proof and permanent marking. Captive marking with light is particularly in great demand when the marking must be clearly legible even under extreme requirements on the tubes throughout their entire life cycle.

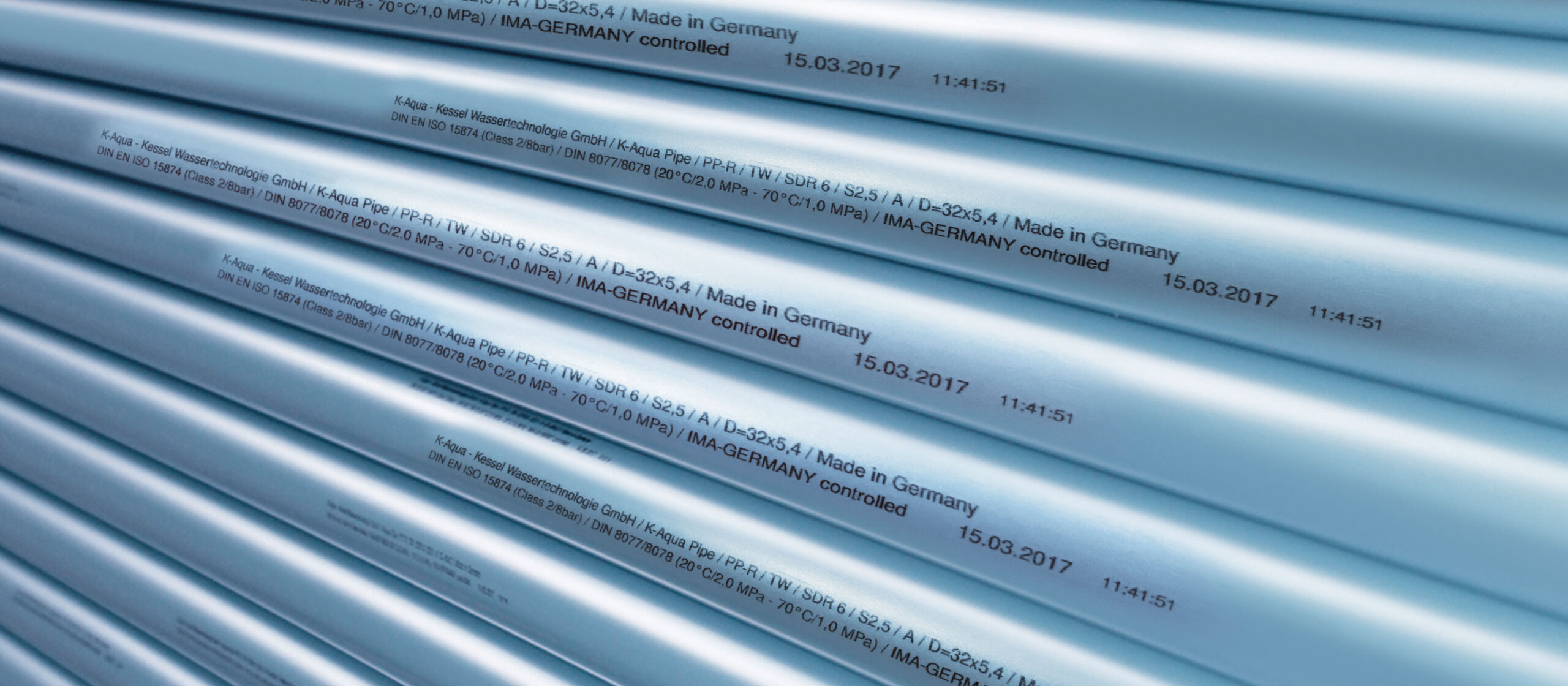

The new generation of the REA JET SC 2.0 Continuous Inkjet Small Character printers will also be presented on the show booth. The system marks smooth, non-absorbent materials such as metals or plastics at high speed. The SC 2.0 marks multiple lines if text in a vertical resolution of 48 pixels. The contact-free ink marking convinces with strong adhesion, high print quality and immediate drying. Equipped with state-of-the-art interfaces, it is the most compact and lightest system in its class.

Visit REA JET at the Tube show in Düsseldorf: Hall 06, Booth 6C1