The German company Kessel Wassertechnologie GmbH, part of the Kessel Group, produces up to 14,000 meters of K-Aqua branded plastic pipes per extrusion line every day. Almost 99% of the pipes are sold to customers in the Middle East for cold and hot water supply – a business that pays off. However, for export purposes, all goods must be marked comprehensively. REA JET experts were commissioned to implement the project.

The plastic pipes are produced strictly in accordance with DIN EN ISO standard 15874. This requires an accurate marking with ISO number, manufacturer’s name, outside diameter, wall thickness, dimension class, material information, maximum operating pressure, production location and production date.

Fast and precise

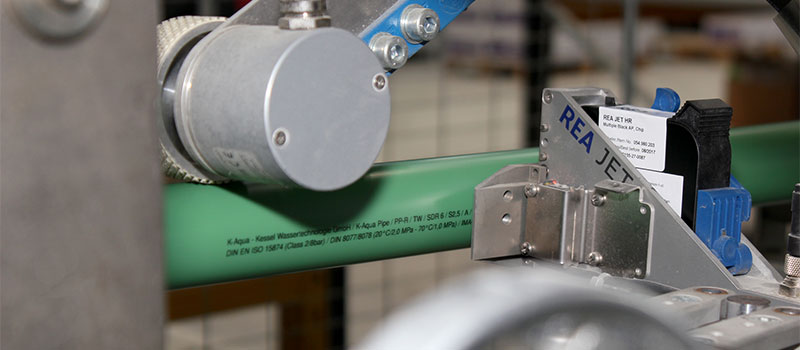

For this demanding task, REA JET experts suggested their thermal inkjet printer REA JET HR. Directly after following the extrusion, pipes are printed contact-freely with a strong adhesion and in high resolution. Thanks to HP cartridge technology, it is maintenance-free, economical in use and immediately ready for operation even after a long standstill period. Another impressive benefit is the consistently precise result at a printing speed of up to 762 m/min. By abstaining from solvent-based inks and thinners, the system is also a clean, environmentally friendly alternative to many small character inkjet printers (CIJ).

In the production hall of K-Aqua, up to 3,500 plastic pipes per machine are produced and marked every day. The single-layer and multi-layer composite pipes with fiber glass reinforcement are available in different colors and, if required, with additional functions such as UV protection for installation on plaster. This is another application where the flexible REA JET HR can score with a wide range of colored, well-adhesive inks.

Customers first

K-Aqua produces exclusively on demand. Thus, the customer’s individual order is always in focus. To satisfy the high requirements, great flexibility is required. Not only the production, but also the marking data must be modified constantly, reports Philipp Nickel, Technical Director at Kessel Wassertechnologie GmbH.

Thus, operation is realized via an input terminal at the production line at K-Aqua. They particularly appreciate how speedy and easily data can be uploaded and adapted on the computer without further conversion. The resulting flexibility and pragmatism represent a significant added value. Thanks to full Unicode support, texts can be printed in almost any global language.

Future-proof solution

Modern interfaces enable an easy integration into the production line as well as a fast data exchange with the production environment. The graphical user interface provides a realistic display of the print content (WYSIWYG). The REA JET HR system is controlled via the uniform operating concept for all REA JET technologies, REA JET TITAN Platform. That makes K-Aqua perfectly prepared for the future in reference to Industry 4.0: If required, users can switch to an operation via touch screen, smartphone, tablet or any browser at any time.

Locational advantage Germany

In order to further increase the marking’s adhesive strength, the static charge of the pipes is reduced by stripping with a brush prior to the marking. This advice came from the REA JET Account Manager. Technical Director Philipp Nickel appreciates the all-round service and the smooth integration of the printer. Both companies are linked by their location in Germany and their Made in Germany label. This synergy boosts exports.

REA JET also develops and produces all coding and marking systems at its headquarters Muehltal, Germany. Thanks to their in-house development and production, they also realize customized applications. The modular technology design facilitates flexible customizations to a wide range of requirements. Thus, every customer receives the appropriate, individually coordinated coding and marking solution.

Successful team

Excellent quality is the success factor of K-Aqua: The polypropylene pipes have a particularly long service life. Thus, they require less replacement. K-Aqua pipes are easy to clean, durable, withstand extreme temperatures and are suitable for drinking water. Consistent customer orientation, high quality and production Made in Germany pay off: The business is booming. Thus, K-Aqua will soon establish further extrusion lines and will rely on REA JET HR printing systems in the future as well.