PACK EXPO International 2024 once again proved itself as a premier event for the packaging and processing industry, breaking previous attendance records and spotlighting major trends and innovations that will shape the future.

With 77,500 total attendees, including 48,000 visitors and 29,500 exhibitor personnel, the expo demonstrated a 19% increase in international attendance compared to 2022. It spanned an impressive 1.32 million net square feet, hosting 2,700 exhibitors showcasing their latest technologies.

Sustainability and Technological Innovation Take Center Stage

Technological advancement was also front and center, particularly around Industry 4.0 and the digital transformation. Exhibitors highlighted how AI, IoT, and machine learning are boosting efficiency and enhancing data-driven decision-making across packaging and processing operations. Automation and robotics further showcased the next level of operational excellence, featuring advancements in automated packaging and processing systems that will drive future industry standards.

Technological advancement was also front and center, particularly around Industry 4.0 and the digital transformation. Exhibitors highlighted how AI, IoT, and machine learning are boosting efficiency and enhancing data-driven decision-making across packaging and processing operations. Automation and robotics further showcased the next level of operational excellence, featuring advancements in automated packaging and processing systems that will drive future industry standards.

Key Conversations at the REA JET Exhibit

Throughout the expo, REA JET’s NEW UP technology attracted considerable interest, especially when it came to case coding and label replacement applications. A noticeable trend among attendees was their shift from preprinted boxes to in-house printing solutions. This move provides businesses with greater flexibility in their operations, allowing them to print specific information as needed and tailor outputs to individual customer requirements.

- The UP combines exceptional speed with cost-effectiveness. With print speeds up to three times faster than traditional methods, it delivers outstanding performance while reducing operational expenses and maintenance needs. This innovation sets a new standard in efficient, high-quality printing solutions.

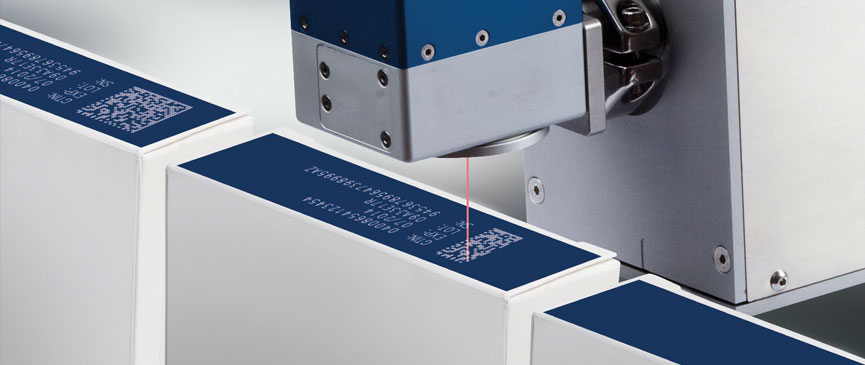

The Push Toward 2D Barcodes and Sunrise 2027

One of the standout topics at the expo was the Sunrise 2027 initiative—the industry’s move from traditional 1D barcodes to 2D barcodes, such as QR codes. This transition, which supports up to 7000 characters of information, promises to revolutionize data capture in the industry.

The benefits of 2D barcodes include:

- Enhanced inventory management capabilities.

- Improved product traceability and consumer trust.

- Opportunities for richer customer engagement through embedded information.

The shift to 2D barcodes is a key component of the smart data capture revolution, positioning the industry for a future where products can communicate a wealth of information to both consumers and supply chain stakeholders.

For REA JET, this trend represents an opportunity to showcase advanced coding and marking solutions that are fully equipped for this new era.

Enhancing Efficiency with Barcode Traceability and Verification Systems

Beyond label replacement, we saw a surge in demand for barcode verification systems, highlighting the growing emphasis on accuracy and quality in coding solutions. As 2D barcodes become increasingly prevalent in the retail sector, the need for reliable scanning and verification has never been more critical. Beyond providing cutting-edge coding and marking systems to generate barcodes, REA JET distinguishes itself as the sole provider of a comprehensive product line dedicated to barcode verification systems, ensuring precision and dependability at every stage of the process.

A Strong Call for Flexibility and Sustainability

REA JET HR 2.0 Universal Touch Controller with HR 2.0 Print Heads

Sustainability and flexibility were recurring themes, not just in technology but in business strategies as well. Companies are prioritizing solutions that allow for adaptability in their packaging lines, reducing reliance on fixed preprinted materials and enabling dynamic printing that aligns with evolving consumer expectations and sustainability standards.

PACK EXPO International 2024 set the stage for the future of the packaging industry.

For companies looking to stay ahead, investing in innovative, flexible coding and marking solutions is essential.

Explore how REA JET can help your business transition seamlessly into the next era of packaging technology. Contact us today to learn more about our cutting-edge solutions and how we can support your in-house printing needs.