Definition of Task

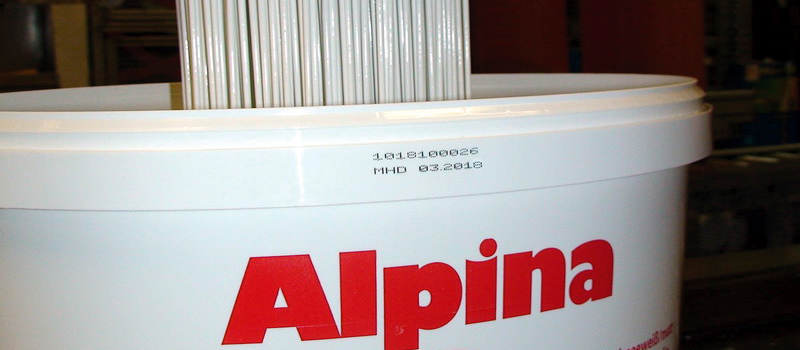

- Coding of synthetic (PP) paint pails and metal paint cans with the expiration date and batch number in many languages

Special Product Specification

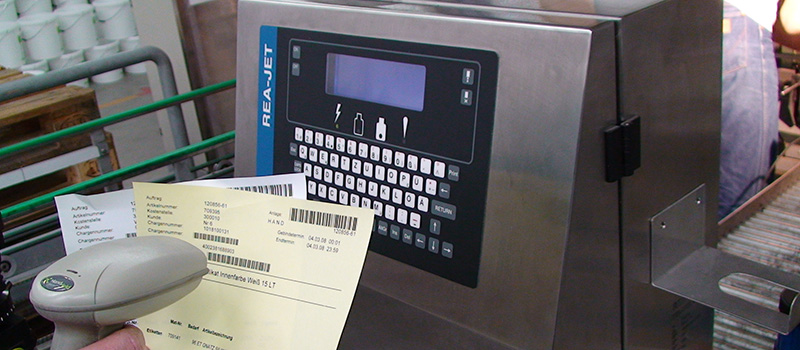

- The assignment of print jobs and automatic printing with the respective batch number is carried out by simply scanning the bar code on the production’s accompanying documents

- REA customized software (Script) has an allowance counter which makes a log of the number of coded products. When the allotted amount has been reached the print job will stop via the autostop function and the conveyor belt will also stop

- A signal light shows the operating personnel when the printing assignment is completed

- Printing of up to three lines at a product speed of between 7 and 30 m/min

- Pails are marked sidewise, metal cans are marked upside down

- High humidity due to the manufacture of latex paint

- Multi-shift operation (24 hours, 6 days a week)

REA JET Solution

- REA JET SC 1.1 Continuous Inkjet Printing System

Advantages of the REA JET Solution

- Printing data imported per scanning of a barcode direct from the production data sheet and automatically printed

- Manual input no longer necessary for operating personnel

- All-in-one solution: coding and marking of products & print job ends after reaching the allotted amount for the production order

- Highly-flexible coding (print text, language) through non-contact coding and marking with inkjet systems – replaces expensive, personnel-extensive and manual labeling

- Various print adjustments (upside down or sidewise)