When it comes to coding and marking products and packaging, laser-based product marking is becoming increasingly established alongside industrial marking with ink.

When ink is used for product marking, the type of ink selected plays a crucial role. Users can choose from an ever-growing selection of inks, which differ with regard to color, light resistance, drying behavior and many other properties. A perfect print result can only be achieved by selecting the optimum ink. Ink very rarely affects the product surface or its properties.

Laser marking, on the other hand, always entails treatment of the material and changes the surface of the substrate to be marked. Various different effects can be achieved depending on the material, the laser and the individual parameter settings. They include engraving, removal of the top layer, color changes and surface foaming.

Important questions

The readability and durability of the laser marking are not the only important factors, however: Producers also need to know whether and how the laser treatment affects the product’s properties. REA’s coding and marking specialists have therefore taken on the task of developing optimum coding and marking systems for almost every conceivable marking application – and providing answers to many more questions, too. One question that frequently arises with laser applications is how they affect the materials to be marked in terms of material weakening, bulging of the material, engraving depths and many other aspects.

Precise answers

In order to provide individual and distinct answers to these questions and eliminate risks for the user, REA JET is investing not only in the development of existing and new coding and marking systems, but also in analysis technology for inspecting and evaluating the marking. As well as the company’s own REA VERIFIER-branded optical code verification devices for 1D and 2D codes, this technology now also includes a digital 3D microscope for quantitative examination of surface structures.

Using this microscope technology, the experts at REA can not only provide visual impressions through simple microscope images, but also make detailed and quantitative statements on the resulting depth profiles for laser marking. In addition to the isolated measurement of one height or depth, these also include precise analysis of the entire marking area with µm accuracy. Numerous further functions enable the marking to be analyzed according to the user’s needs and preferences.

These include the creation of a sectional profile, determination of the maximum height and depth on the basis of a two-dimensional depth profile, determination of the distance between the two, and definition of the volume. REA’s coding and marking specialists can thus analyze every laser pattern in detail and provide laser technology users with well-founded information on the impact of the laser marking on the surface and wall thickness of their products.

Material weakening?

Beverage bottlers today use laser coding to mark nearly 100% of their products. When PET bottles are engraved with a standard CO2 laser at 10.6 µm, there is a potential risk of weakening or even perforating the material. The marking pushes the material to the side, leaving a distinct engraving with material bulging on the sides. This in turn leads to a significant, undesired reduction in the wall strength of the PET material.

In order to avoid this, CO2 laser with a wavelength of 9.3 µm are used today. In this scenario, microscope technology clearly shows how laser marking with different wavelengths affects the material surface.

It is thus evident that marking at 9.3 µm does not result in engraving, but foams the material. This actually strengthens the material, which can lead to improved product stability.

Corrosion protection?

Other applications aim to process the top layer of a product with the laser. Since this layer often has not just an aesthetic function, but also protects the substrate below, the challenge is to achieve maximum readability of the laser marking while removing as little as possible of the layer. Thanks to state-of-the-art microscope technology, the experts at REA can determine the exact depth to which the laser beam penetrates the material.

This means they can ensure that the top layer is only removed up to a precisely defined thickness, so the protective function of the layer remains unaffected.

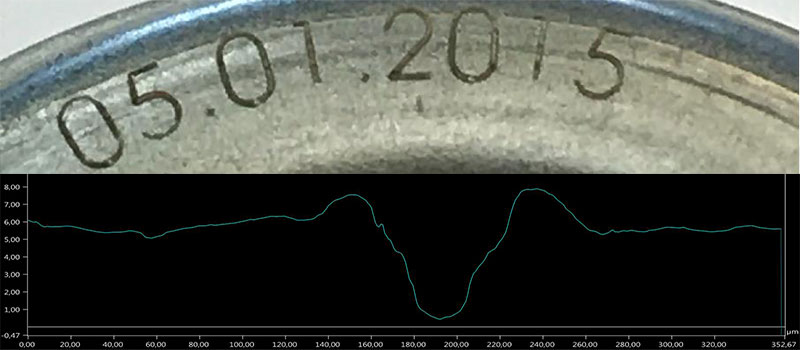

Galvanizing metallic surfaces to protect them from corrosion is a common application in the metal processing sector. The sectional view of the microscope image shows a maximum penetration depth of 6 µm. This verifiably ensures that corrosion protection remains intact even after the laser marking.

Lifelong readability?

In contrast, there are also many applications where the engraving needs to be as deep as possible – for example when the engraving of metallic materials is to remain visible even after painting.

When rubber is laser marked, a minimum depth is often needed to ensure that the marking remains easily readable throughout the lifespan of the product, even if the uppermost layers of the material wear off. One such example is the marking of rubber with QR codes. Under the microscope, an engraving depth of 250 µm is measured. In this case, the analysis confirms a corresponding durability of the code, which can still be read even after heavy material abrasion.

Material bulging?

In addition to classic marking tasks, laser systems are also used for cutting parts out of material. For instance, lasers can be used to perforate rolled plastic products. The quantity of material that may accumulate at the edges of the holes and cause a bulge is an issue here. This can cause the material thickness to vary, resulting in undesired effects when the product is rolled. With its microscope technology, REA can provide exact information on bulging and material characteristics.

In this case, the bulging of material when cutting the plastic film was found to be max. 100 µm (determination of the extreme value), which did not obstruct the rolling process.

Conclusion

Use of the 3D microscope has significantly improved the quality of consulting at REA JET. The well-founded analysis method makes it possible to select and recommend the best laser system for the customer’s specific application from a host of possible system configurations. This includes the type of laser marker (fiber laser or CO2 laser), the wavelength, the focal length of the focusing lens, the scanner head and the marking parameters to be chosen.

REA’s experts can also provide users with well-founded and precise answers to questions on the laser marking process and its effect on the material. This information is an advantage that should not be underestimated.

Further information on REA JET and the full-range provider’s industrial coding and marking technologies and solutions is available at www.rea-jet.com.