Prior to implementing REA JET, Penmar Industries tested two coding and marking companies that failed due to poor performance quality, speed capacity, costly maintenance issues, and inferior inks. They were ultimately introduced to REA JET through a positive referral from another leading label converter in the industry.

About Penmar Industries Inc.

Penmar Industries is a leader in today's competitive tape, label, and packaging markets. Founded in 1964, Penmar provides tape converting and label solutions for manufacturing, supply chain, and packaging companies in North America, Europe, India, China, and the Caribbean.

Located in Stratford, CT, Penmar continues to expand its facilities for manufacturing labels and the number of industries and markets they serve.

▼ Challenge

Penmar Industries is a proactive problem solver for its clients. They were in search of a more reliable solution for several challenges they were facing, including; a fool-proof process for printing on the back of labels, high speed variable-data printing, and customized ink formulations to name a few.

"Finding a suitable ink that would work was a hurdle because we're printing the back liner for label material that can either be polyester or polyethylene which can be a tricky substrate to mark.

We tried a couple of other inkjet technology vendors that each came up short of our expectations. It was apparent we weren't a priority. While visiting another label converter we partner with, I saw they had a working solution that appeared to be just what we needed. I asked how they were doing it, and the answer was REA JET. That began a relationship that has been painless from day one."

Rick Cipot, Operations & General Manager at Penmar Industries, Inc.

▼ Solution

REA JET equipment provides seamless integration and keeps pace with speed of production.

Jim Schindler, REA JET Regional Account Manager

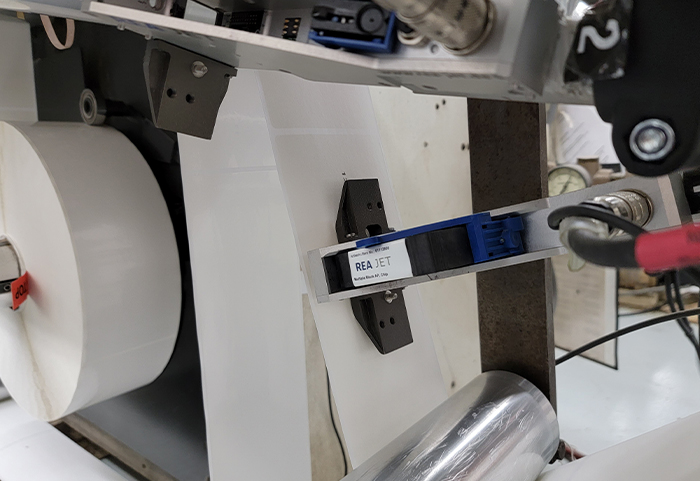

After multiple on-site visits and running some initial sample tests, it was determined that the best course of action would be to implement REA JET’s High Resolution inkjet technology (REA JET HR). Penmar Industries was impressed with the flexibility of the equipment, the ease of use and the fact that it is virtually maintenance free. With a cartridge as the printhead, being able to easily swap them out when needed was an overall game changer.

Per Penmar's specifications, the REA JET equipment provides seamless integration and keeps pace with the speed of their production line. The equipment cost was very reasonable, and maintenance is not an issue.

▼ Results

Since bringing in the REA JET HR, Penmar has attracted a sizable amount of new business.

As tracking and traceability of products continues to become more critical in manufacturing, it is crucial that labels be printed with clear, legible data.

Penmar Industries is so pleased with the performance of their REA JET technology and inks they are planning an extensive expansion of their capabilities, including a new digital department.

In addition to their conventional label printing on flexographic presses, the new digital department will enable Penmar to serve a broader array of clients across more industries.

"Our new digital press has been built to our specifications. It's not something off the shelf. Before we even started discussing building the press, I wanted to ensure that we could incorporate REA JET technology into our label finishing process. We're putting four print heads on the unit, and it will be seamless.

Jim has been there for us throughout this entire process. He asked the right questions and gave me the correct answers. He knows what he's doing."

Rick Cipot, Operations & General Manager at Penmar Industries, Inc.

The right technology for your coding and marking needs

Contact REA JET

- Call Us: 440-232-0555

- Email Us: sales@reajetus.com