Today, there is a much more efficient way to mark blueprints on concrete that reduces labor, time, inaccuracies and do-overs. Combining the best in robotics with the best in inkjet technology adds something completely new to the construction industry.

"Among every customer we've ever talked to, everybody knows this is the next step. This is the next tool to do this part of the job. And we are working to shape the future of construction. Robotic layout is the next step and it’s going to happen. It's just a matter of when. And that's the story we are showing and telling with confidence."

Logan Farrell, CoFounder and CTO of Rugged Robotics

About Rugged Robotics

Rugged Robotics is a Houston-based construction technology company. Their primary product tackles the challenge of field layout and replaces slow, error-prone, manual layout with an autonomous vehicle that marks fully coordinated A/E designs directly onto unfinished floors. The team is past prototyping and testing and is now starting to scale commercially with several multi-billion-dollar general contractors.

Opportunity

Approximately three years ago, Rugged Robotics recognized an opportunity to engineer robotic automation to replace the manual and time-consuming process of marking concrete floors for build-out.

While other companies in the industry were using robotic total stations, Rugged Robotics took it upon themselves to create a much smarter solution.

"Our end goal was to automate the things that make sense to automate in commercial construction."

Logan Farrell, CoFounder and CTO of Rugged Robotics

Rugged Robotics didn’t want to reinvent the wheel when it came to marking so they searched the industrial inkjet market and reached out to a few different companies, including REA JET US.

"It's a very forward-thinking type of robotics technology and we’ve had to customize some solutions on this project. I think that's what Rugged Robotics values from us – our flexibility."

Richard Hultberg, REA JET US Regional Account Manager

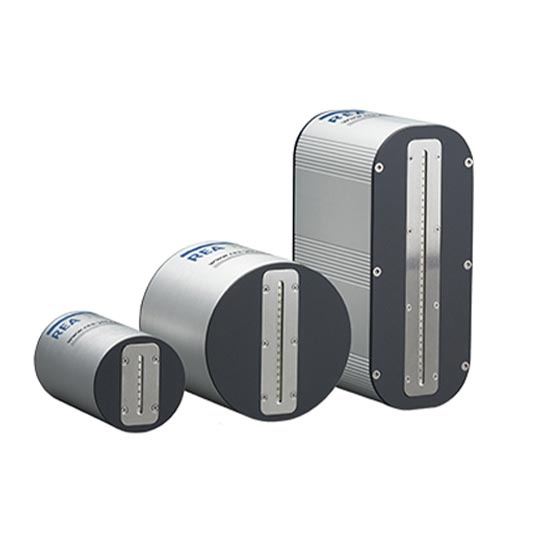

REA JET DOD 2.0 Large Character Print Head marking construction materials

▼ Solution

Engineers talking to Engineers

By combining REA JET’s technology with that of Rugged Robotics, and with the help of both engineering teams, Rugged Robotics was able to make their robot small, sleek and as fast as possible

"We already had the robot, REA JET came in and was able to mount their large character drop-on-demand print head onto it. Their technology was able to mark blueprints on the concrete floor which helped subcontractors identify what needs to go where based on the blueprints that are drawn on the floor.”

Logan Farrell, CoFounder and CTO of Rugged Robotics

REA JET DOD 2.0

The new generation of Large Character Inkjet Systems

The silver print heads - determined to further improve our legendary sturdy REA JET DOD large character print head, we took into consideration two common customer requirements:

- Desire to duplicate production speed potential to more than 600 m/min

- Multiplication of print durability by lowering wear and tear

▼ Results

Rugged Robotics reduces labor costs and compliance concerns.

One of the big areas of rework is in compliance.

"We just recently added the ability to mark a 60 inch circle for ADA bathrooms so that you can guarantee you're going to pass your inspection for that bathroom. Instead of someone making a mark that’s six inches off, we're marking it correctly from the beginning. Not having to worry about that as much is one of the big things we're solving."

Logan Farrell, CoFounder and CTO of Rugged Robotics

There is another difference between Rugged Robotics and their competitors.

Rugged Robotics is providing their technology as a service. Their team will come out and do the actual layout, whereas many competitors lease robots and it falls on their customers to handle that on their own.

"I think what really sealed the deal was when we first spoke to Richard at REA JET we realized these guys really know their stuff. We liked the product and the service and we've been working with REA JET ever since."

Logan Farrell, CoFounder and CTO of Rugged Robotics

The right technology for your coding and marking needs

Contact REA JET

- Call Us: 440-232-0555

- Email Us: sales@reajetus.com