Identifying metal materials using coding and marking is beneficial for many processes along the supply chain, including counting inventory, and overseeing quality control. Oftentimes, it is a regulatory requirement. But, do you know just how long this practice has been used by manufacturers?

Ever since humans began producing goods, artisans marked their products with their signature or insignia. These earliest markings ensured the quality and authenticity of the product. The original markings were written, painted, or carved by hand.

When The Industrial Revolution increased the speed of production across industries, the yield of products rose to unparalleled quantities. Buyers wanted proper identification of products and materials, and therefore, industrial coding and marking were born.

The Industrial Revolution and Coding & Marking

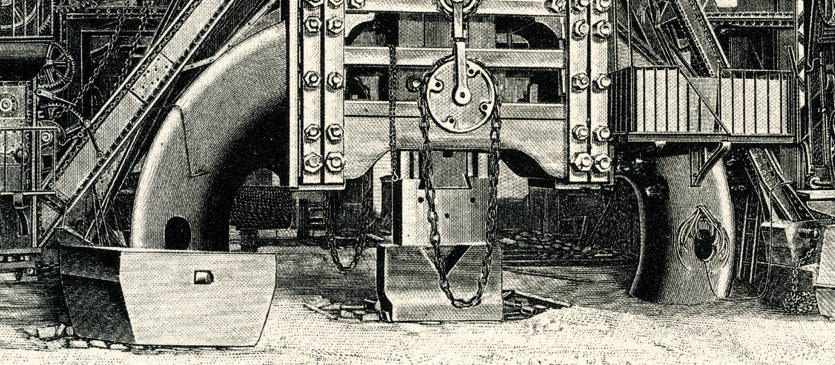

The invention of industrial coding is not recorded as one specific moment, but it can be traced back to the invention of the steam hammer by James Nasmyth in 1839. The steam hammer was created to morph large steel and iron materials. This invention sped up production, and also created a more consistent product. Manufacturers could homogenize their products and ship large batches of uniform products across the country and the world.

As products became more alike and began traveling further from their point of creation, coding and marking became crucial to accurate tracking of products.

The Beginning of Regulatory Marking

Coding and marking of products allowed for easy reference for sellers and buyers. Codes can be modified to share a wealth of information between manufacturers and consumers.

Government regulation began to rise in the 1890s to offset issues caused by the Industrial Revolution. These regulations targeted problems surrounding quality, worker health, and public safety. Inspectors began to track goods, and what began as a helpful tool for sellers and consumers, became a requirement for compliance with regulatory oversight.

But, expectations for marking and the demand for more products quickly overwhelmed the available methods. Another revolution needed to occur within industrial coding and marking.

Changes to the Coding and Marking Industry

During World War II, manufacturing shifted toward supporting the war effort, as well as trying to fulfill consumer demand back home. More people joined the workforce. With yet another round of increased production, new methods for coding and marking were invented. Steel stamping and electrochemical etching could be used on an assembly line and produced a more durable and higher-resolution mark.

In the 1960s, lasers became prominent in the coding and marking industry, and they remain in use today. Lasers are used on a wide variety of products, including plastic, steel, metal, and almost any other durable material. They can be programmed from one job to another and are faster, more reliable, more durable, and precise. Laser marking brought a new level of flexibility and speed to factories worldwide.

Coding and Marking Today

Another Industrial Revolution is underway today. Industries are increasingly employing smart technologies and automation to improve their manufacturing speed and quality while lowering costs to meet the expectations of today’s consumers.

Almost every industry today uses metal marking for many of the same reasons it has been used throughout history, for traceability and regulatory demands, but the methods are more efficient than ever. Lasers have been modernized and improved, and inkjet technologies have been developed.

Manufacturers today expect modern technology that can withstand the often harsh conditions of production facilities.

For over 30 years REA JET has been committed to providing state of the art technology along with top-of-the-line customer service to our customers and partners worldwide. Our REA SYSTEMS division offers automated coding and marking solutions made specifically for the steel industry and high-heat applications. REA JET technology provides excellent flexibility and reliability to meet the day-to-day needs of a demanding production environment. With a wide range of systems available, REA JET has the solutions to help meet ever-changing coding and marking requirements across all industries.